- Home

- Technology

High Performance Conformal Coating System SC-900

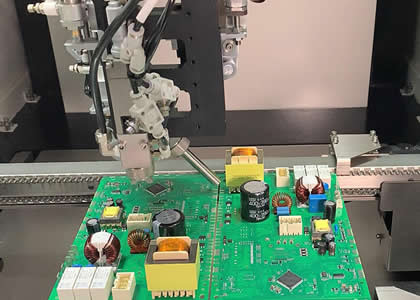

High strength welding frame, X/Y/Z/R axis adopt Panasonic servo motor and ball screw

● High strength welding frame with high performance Panasonic servo motor and it's driving system which can reach ±0.05 mm repeatibility to ensure accurate and stable coating process.

High Performance Conformal Coating System

2 tiltable valves with ±170 degree rotation can do side coating for tall components

● Sometimes there are coating area blocked by components or under components where valve can not reach.

● SC-900 is equipped with R axis which can rotate ±170 degree, the rotable and tiltable needle valve and narrow spray valve can perfectly solve this problem to ensure no dead angle coating process.

A variety of high precision valves can meet different coating requirements

● SC-900 conformal coating system is standardly equipped with 3precision valves which can meet most of coating requirements.

Optional film coating valve is choosable.

Needle Dispensing valve

Dispensing line width: min. 1.5mm

Air pressure: 0.1-0.4Mpa

Applied to max viscosity of the glue: 500cps

Narrow spray valve

Spraying swath: 6-10mm

edge definition: 2mm

Air pressure:0.2-0.4Mpa

Applied to max viscosity of the glue: 1000cps

Wide spray valve

Spraying swath: 15-30mm

edge definition : 3mm

Air pressure: 0.1-0.4Mpa

Applied to max viscosity of the glue: 800cps

Film coating valve V-5000

Spraying swath: 8-15mm

Air pressure: 0.2-0.4Mpa

Applied to max viscosity of the glue: 100cps

Nozzle inside diameter: Standard: 0.18mm, Option: 0.15mm

[Learn more Optional]

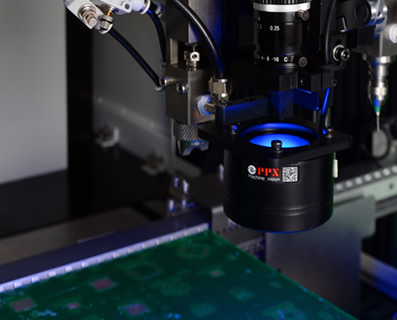

CCD system can be used for programming and mark recognition

● SC-900 selective coating system is equipped with CCD system which can recoginze mark and automatically correct the offset of coordinate.

● Also can use CCD teach coating path for programming.

Glue weighing system can avoid missing coating

● SC-900 selective coating system can be equipped with weighing scale for 10L material tank, when the material weight is lower than setting value, system will alarm to remind operator to add material to avoid missing coating.

Bar code reading system

● Barcode reading system which can automatically call program related to barcode.

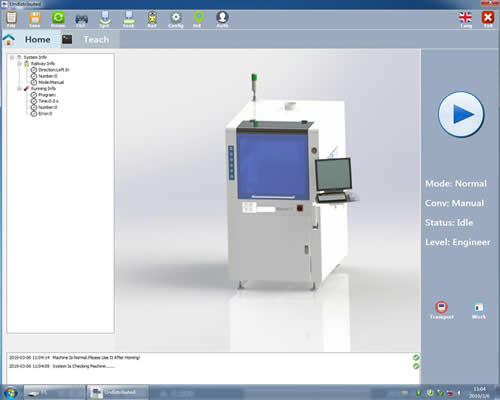

Professional coating software easily meet various requirement of coating prcoess

Professional coating software has funcitons as below :

● 2 programming method: direct teaching with valve, teaching with CCD, easy to operate.

● Panel coating process: for PCBs on one panel, only make one program and set the distance of the PCBs on the panel to coat all the PCBs on the panel.

● when PCB missed or mark recognition failed, system give operation options as: continue coating, skip to coat next board, stop coating process.

● Area coating programming: easily creat a area coating process by set 2 points on the PCB.

● Coating parameter batch modification, easily change coating path offset value and coating parameters.

● Automatically call programs by barcode.

Copyright © 2025. 1clicksmt-conformalcoating. All Rights Reserved