- Home

- Solution

Solution

High Performance 4 Axis Selective Coating Machine SC-900

1. High strength welding frame, X/Y/Z/R axis adopt Panasonic servo motor and ball screw.

2. Tiltable narrow spray valve and needle valve with ±170 degree rotation.

3. Equipped with 3 high precision valves: narrow spray valve, needle valve, wide spray valve.

4. CCD system for programming and mark recognition.

5. Glue weighing system.

6. Barcode reading system for automatically call program.

7. Professional coating software based on windows 7 OS.

8. Standard equipped with 10L material tank and 2L cleaning tank

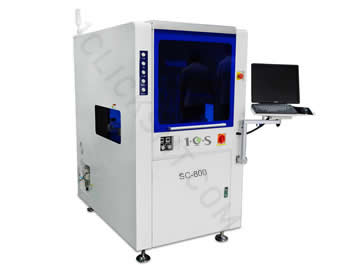

High Performance 3 Axis Selective Coating Machine SC-800

1. Machine adopt high strength welding frame, X/Y/Z axis adopt Panasonic servo motor and ball screw to ensure high speed and stable running.

2. A variety of high precision valves can meet different coating requirements.

3. Optional CCD system can be used for programming and mark recognition.

4. Glue weighing system can avoid missing coating.

5. Optional barcode reading system which can automatically call program according to barcode for double side coating line.

6. Professional coating software easily meet various requirement of coating prcoess.

7. Industrial PC, windows operation system, full english interface, very easy to use.

8. Customized whole coating line is available.

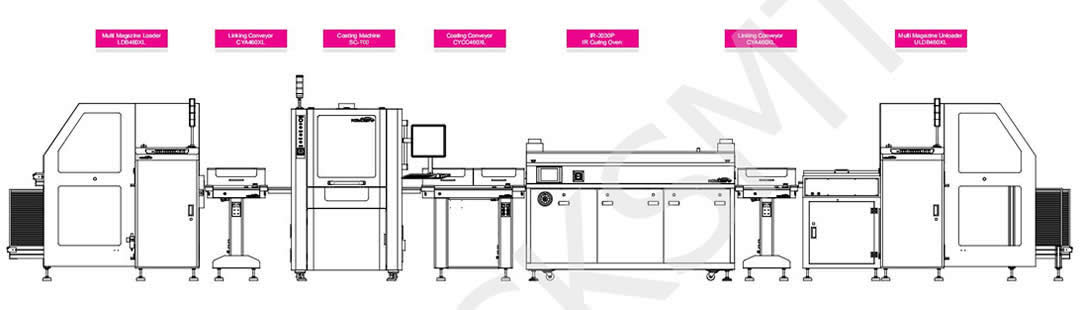

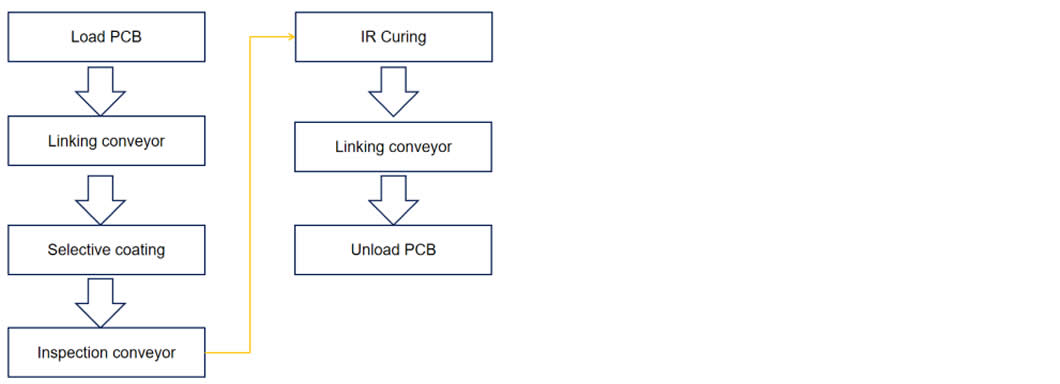

Selective coating with IR curing line Solution

Selective coating with IR curing line process

1CS Selective coating line advantage

● Provide one -station selective coating line solution.

● Professional team and support for customer

● Selective coating machine SC-900

— 4 axis Selective Coating Machine ensures no dead angle coating.

— Solid steel platform

— High quality parts

— High precision valve

— Professional coating software

● Quality PCB handling machine and conveyors

● Curing Machine

— High precision temperature control, high quality light, uniform heating, ensure curing quality.

Copyright © 2025. 1clicksmt-conformalcoating. All Rights Reserved