Products

Peter 2019-05-31 9:05:11 SC-445 Selective Coating Machine adopt high precision servo driving system and high precison valve which provide a clean, highly effecient coating process. High prescion valve can meet different coating demands. The tiltable device ensure no dead angle for coating. The maximum coating size can reach 400mm*450mm.

Overview

SC-445 Selective Coating Machine adopt high precision servo driving system and high precison valve which provide a clean, highly effecient coating process.High prescion valve can meet different coating demands. The tiltable device ensure no dead angle for coating. The maximum coating size can reach 400mm*450mm with SC-445.

● X,Y,Z,R axis servo motor with it's driving system.

● High precison coating valve.

● Glue tank weighing system (option).

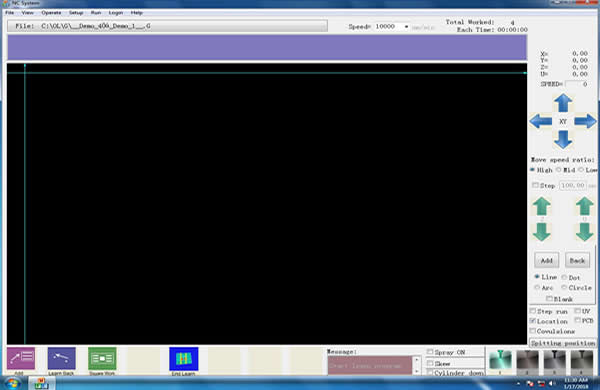

● Industrial PC and windows 7 operation system, full English interface.

● Max 400*450mm PCB width capable.

Details

|

|

● Streamline design of machine, open machine from front, easy to approach valve assemblings and conveyor system. |

|

|

● Close loop X,Y,Z R axis motion system, ball screw drive with rail & slider, make the valve assembly moving smooth. |

|

|

● Windows 7 based OS, full english software. Direct teach with valve, easy to operate. |

|

|

● CE ceritificated electrical parts and wiring, Reliable quality and durability. |

Features

4 Axis Selective Coating Machine SC-445 Features:

● 4 axis Selective Coating Machine adopt ball screw and dual linear guide rail, ensure smooth and low nosie movement, +/-90 degree rotable R axis with optional tilt device ensures no dead angle coating.

● solid steel platform provide a stable base for machine, reduce vibration and enhance machine running life.

● High precision servo motor and driving system make the position repeatibilty can reach 0.05mm, high speed response and movement.

● High precision servo motor and driving system make the position repeatibilty can reach 0.05mm, high speed response and movement.

● Equipped with motorized width adjustment mechanism.

● Optional glue weighing system can avoid missing coating.

● Air pressure detector is standard configuration for safety and ensures coating quality.

● Equipped with UV lamp for coating detection.

● Industrial PC, windows operation system, full english interface, very easy to use.

Specification

| Model | SC-445 |

|---|---|

| Work Area | L400mm*W450mm |

| Axis number | X,Y,Z,R axis(+/-90 degree rotable ) |

| Max Work Movement Speed | Max 800mm/s |

| Standard Valve | Narrow spray valve, needle valve |

| Valve tilting device | narrow spray valve and needle spray valve with tilt angle 35° |

| Optional valve | Film coating valve |

| Max PCB Component Height | 70mm |

| Programming | teaching by valve |

| Repeatable Accuracy | +/- 0.05mm |

| Conveyor Height | 920mm±20mm |

| Conveyor direction | only left to right |

| Conveyor Speed | 0~3M/min |

| Width adjustment | motorized width adjustment |

| Operation system | English Windows 7 |

| Glue Tank | 10L glue tank *1set, 2L cleaning tank * 1set |

| Power Supply | AC220V 50Hz,1P |

| Total Power | 2 KW |

| Air Requirement | 0.5-0.7Mpa |

| Overall Size W*D*H | L1270mm*W1630mm*H1750mm |

| Weight | 535KG |

Valve options and specifications

|

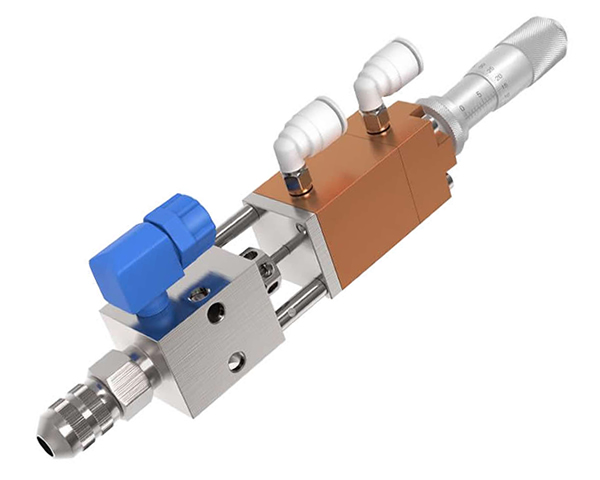

Needle Dispensing valve |

Needle Dispensing valve is applied to areas where: 1. components are close to keep-out areas. 2. tall component require support. 3. extra glue is required. 4. glue is needed on the edge or under a component. |

|

|

|

|

● Dispensing line width: min. 2mm ● Air pressure: 0.1-0.4Mpa ● Applied to max viscosity of the glue: 1000cps |

|

|

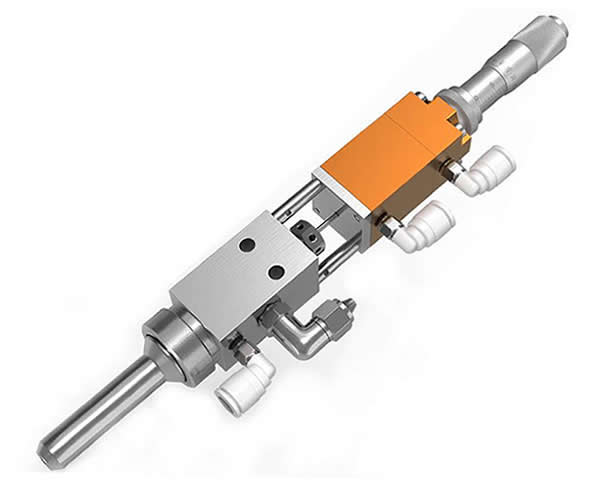

Narrow spray valve |

● Coating thickness can be adjusted by changing air pressure and moving speed. ● Coating width can be adjusted by changing air pressure. ● Narrow spray valve is applied to areas where: 1.most of coating. |

|

|

|

|

● Spraying swath: 6-10mm ● edge definition: 1mm ● Valve stoke: 0.01mm-5mm ● Air pressure: 0.2-0.4Mpa ● Applied to max viscosity of the glue: 1000cps |

|

|

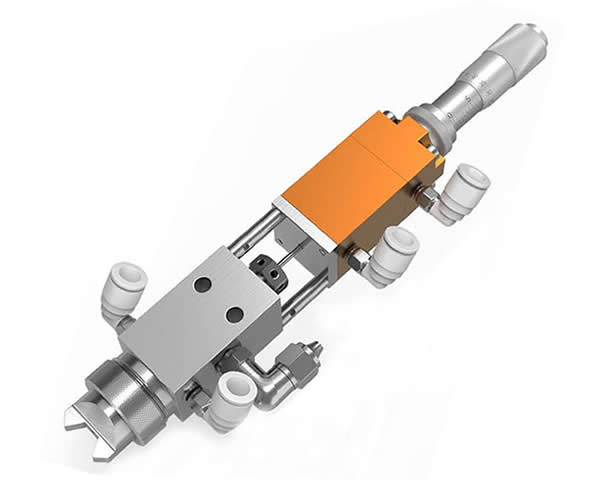

Wide spray valve |

● big spray swath, high efficiency. Coating thickness can be adjusted by changing air pressure and moving speed. ● Coating width cand be adjusted by changing air pressure. ● wide spray valve is applied to areas where: 1.large coating area without barrier. |

|

|

|

|

● Spraying swath: 15-30mm ● edge definition: 3mm ● Air pressure: 0.1-0.4Mpa ● Applied to max viscosity of the glue: 1000cps |

|

|

Selective Coating Machine Valve specification |

|||

|

Valve parameter |

Needle valve | Narrow spray valve | Wide spray valve |

|

spraying swath |

min dot size: 2mm |

6-10mm |

15-30mm |

|

air pressure |

0.2-0.4Mpa |

0.2-0.4Mpa |

0.2-0.4Mpa |

|

applied to max glue viscosity |

1000 cps |

1000 cps |

1000 cps |

|

edge definition |

/ |

1mm |

3 mm |

|

applied to |

1.components are close to keep-out areas. |

1.atomazation film can be adjusted by air pressure and moving speed, applied to most of product. |

1. big spray swath, highefficiency, applied to large coating area without barrier. |

|

2. tall component require support. |

|||

|

3. extra glue is required. |

|||

|

4. glue is needed on the edge or under a component. |

|||

Configuration

Standard configuration

● X/Y/Z/R 4 Axis Selective Coating Machine.

● Industrial PC, monitor, Keyboard, mouse.

● 4 aix driving system.

● Alarm light.

● Narrow spray valve with tilting device *1set

● Needle valve with tilting device *1set.

● Motorized width adjustment system.

● 10L pressure tank *1set.

● 2L cleaning tank *1set.

● Ultraviolet inspection lamp

● 1 year parts warranty.

Optional configuration:

● Film coating valve 1 set

● Glue weighing system for empty glue tank detection 1 set

● PCB clamping system 1 set

● 10L pressure tank (for B glue tank) 1 set

● Customized power supply 1PH, 110V/60HZ 1 set

What options are available ?

Needle Dispensing valve

Dispensing line width: min. 1.5mm

Narrow spray valve

Spraying swath: 6-10mm

Wide spray valve

Spraying swath: 15-30mm

Film coating valve V-5000

Spraying swath: 8-15mm

Glue weighing system can avoid missing coating

Bar code reading system

Material Tank

10L material pressure tank. 2L cleaning pressure tank.

Copyright © 2025. 1clicksmt-conformalcoating. All Rights Reserved